Initial Pinch Rolls

The Hydraulic Initial-Pinch Plate Rolls is designed for job-shop fabricator to bend the thin plate job easy and fast. There are 3-roll and 4-Roll type for choice. The hydraulic powered adjustment and digital readout make repeatability on pieces super easy. The economic price makes it to be the most popular machine of year.

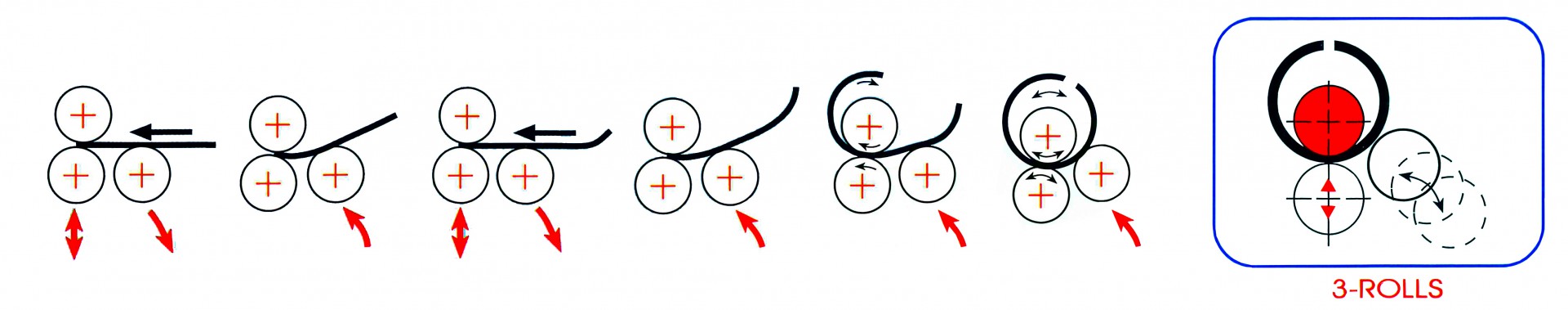

Three-Roll Plate Rolls

The Hydraulic Initial-Pinch Plate Rolls is designed for job-shop fabricator to bend the thin plate job easy and fast. The asymmetric design provides pre-bending capability on the machine. The Quick and Easy pinch gauge adjustment provides the consistent positioning of the lower pinch roll is critical to rolling consistent quality cylinders. By simply inserting a small tab of the material thickness to be rolled into the pinch gauge control, the lower pinch roll is properly positioned to ensure that consistency. A standard LED Readout provides fast and easy positioning of the rear bending roll for repetitive work. Other standard features include Direct-Drive Design, cone rolling attachment, rolls heat treated to 50Rc. The long list of standard features together with competitive pricing make it becomes our Most Popular Product of Year.

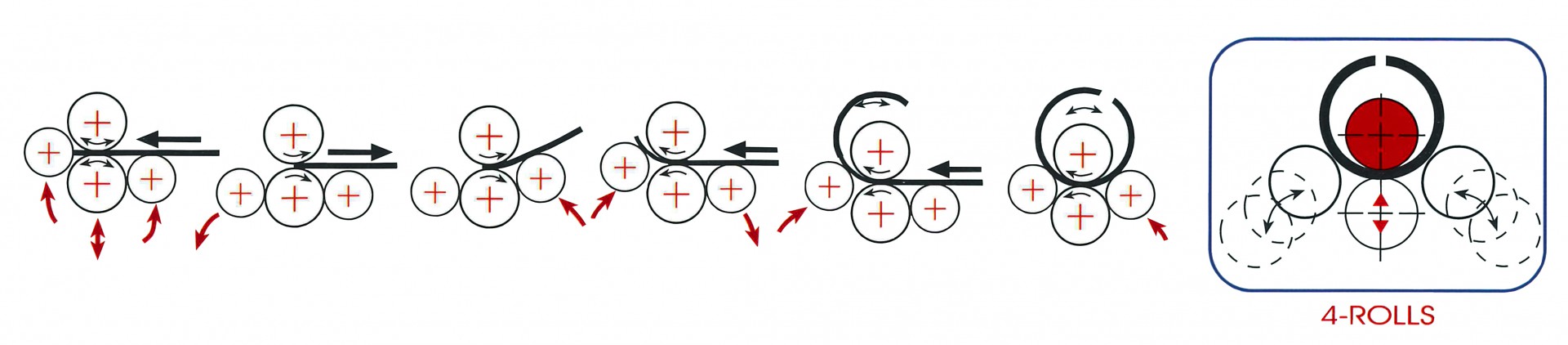

How it works

Standard Equipment

- Direct-Drive Design is featuring constant and powerful torque direct to the roll rotation.

- Sumitomo Cyclo® 6000 Gearless Speed Reducer.

- Spherical roller bearings on all rolls for longevity and constant use.

- Hydraulically powered rear bending roll. Raise and lower the bending roll hydraulically rather than a hand wheel seen on other brands.

- Power tilting rear bending roll for cone rolling.

- Digital readout for position of rear bending roll.

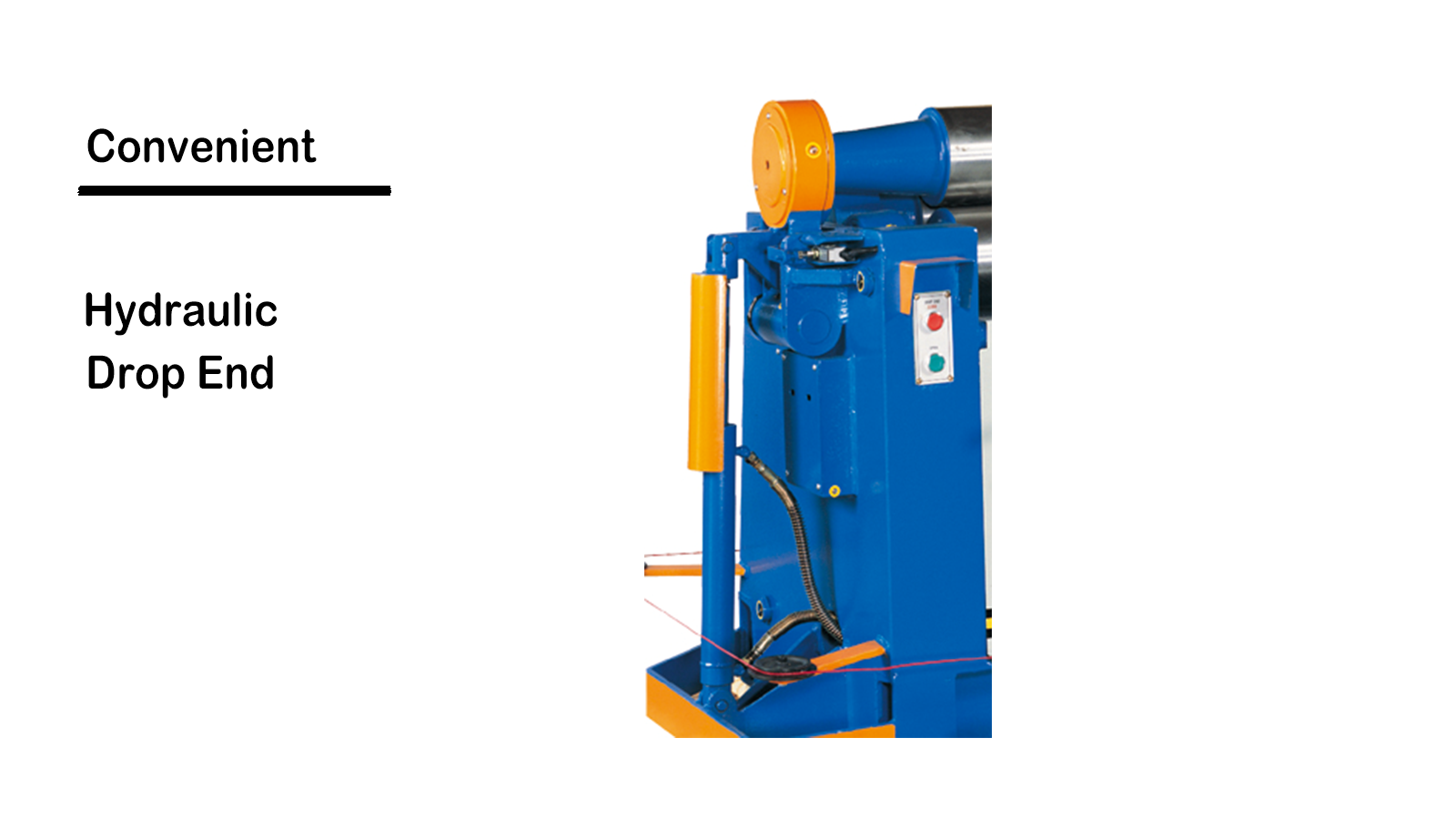

- Hydraulically operated drop-end for quick removal of rolled product rather than using a pivoting roll.

- Quick and Easy hydraulic lower pinch roll adjustment with pinch gauge control.

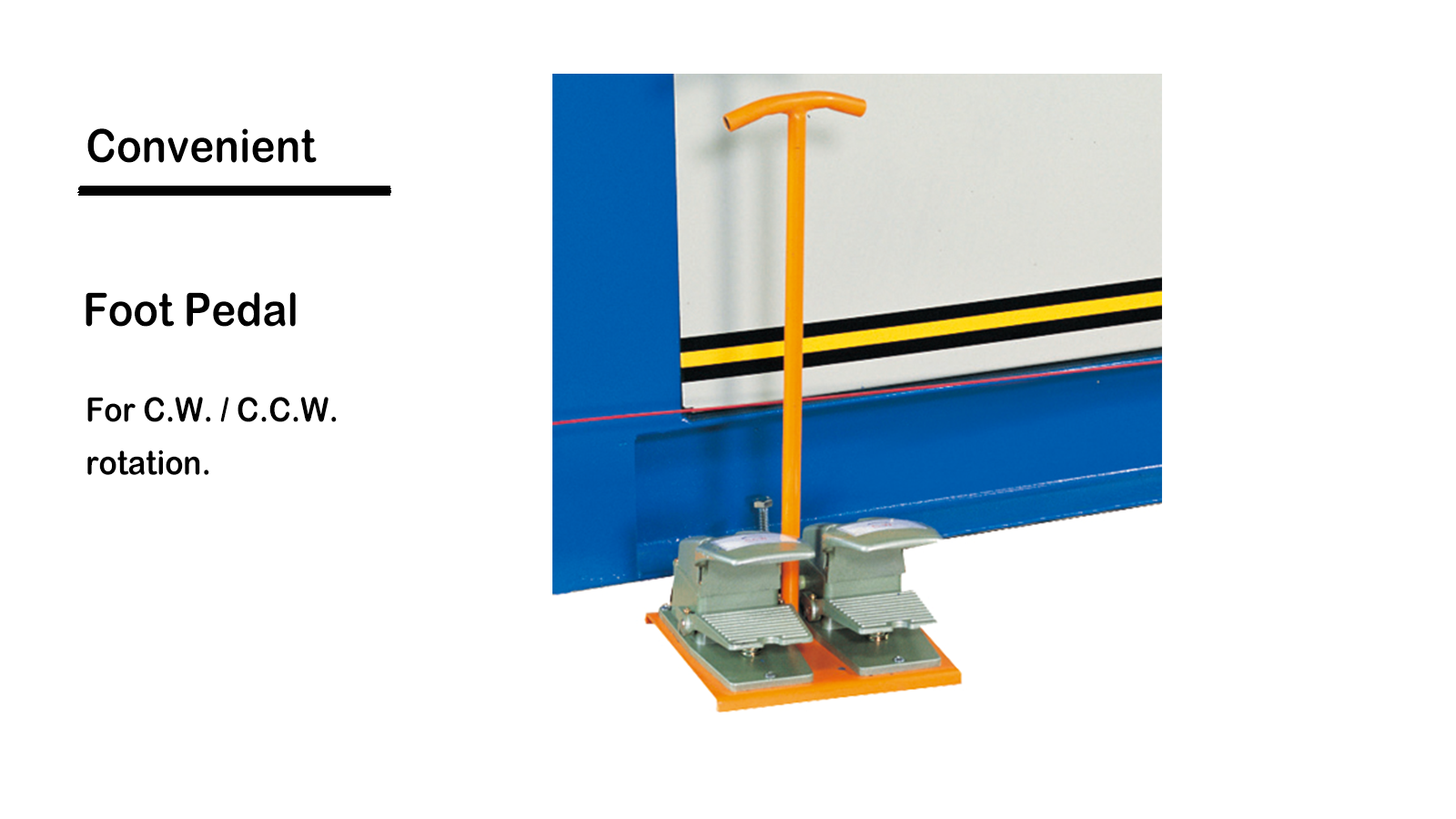

- Dual Forward/Reverse rotation controls – Console mounted and foot pedal.

- Upper and lower pinch rolls driven with direct gear contact.

- All rolls heat treated to 50 Rc.

- Manual tilt of the lower pinch roll.

- Adjusting tools, pinch gauge stock, technical manual

Optional Equipment

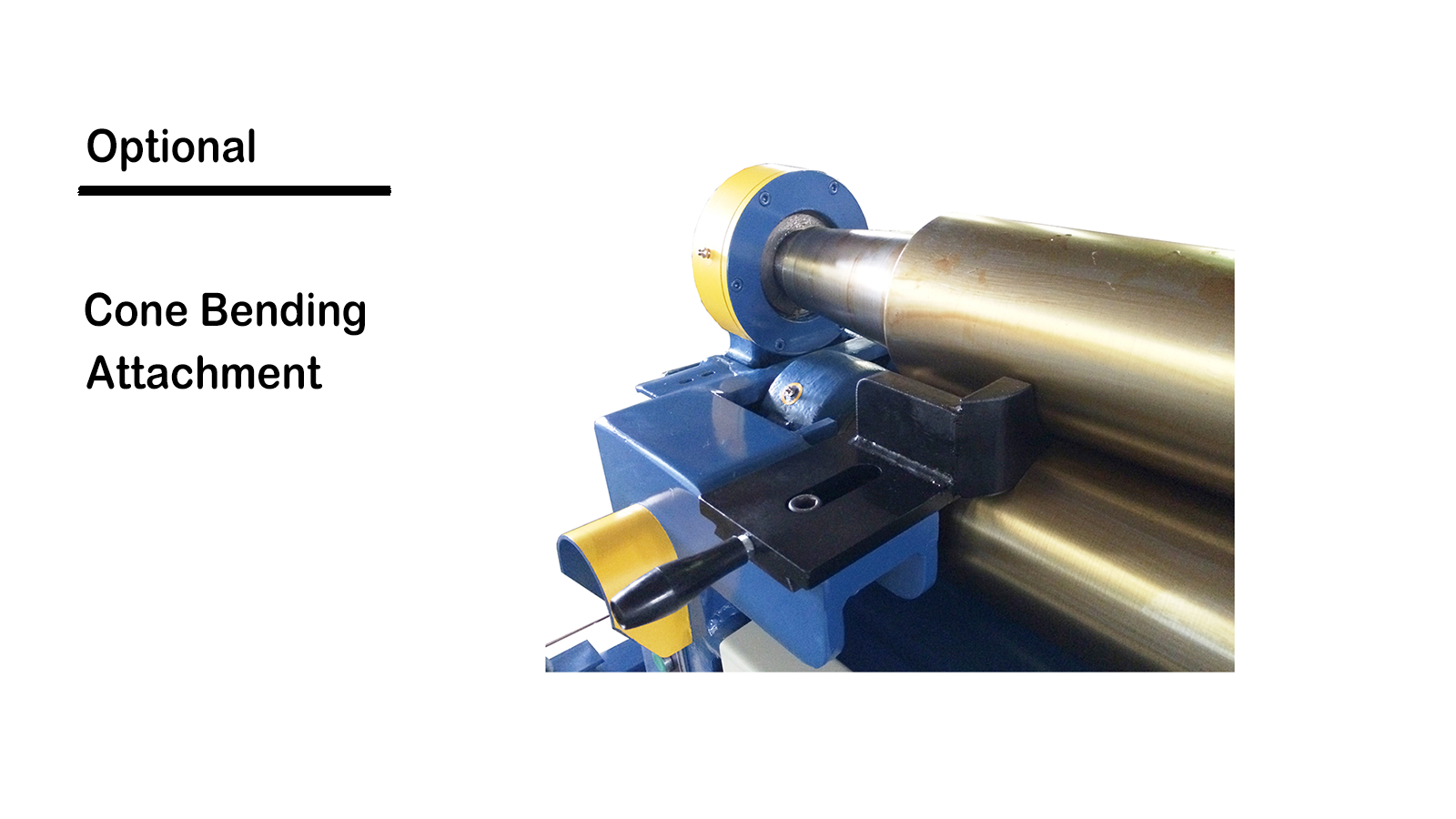

- Cone bending attachment.

- Cable type Emergency stop device.

- Infinitely Variable Speed Control.

- Control Panel on Wheels.

- Top Supports

Four-Roll Plate Rolls

The 4-Roll double-pinch bending rolls feature hydraulic adjustment of the bending rolls and the lower pinch roll with separate convenient pinch pressure adjustment. In addition, both bending rolls are hydraulically tiltable for cone rolling, and the hydraulic drop end makes it simple to remove the completed cylinder from the rolls. Other standard features include Direct-Drive Design, cone rolling attachment, rolls heat treated to 50Rc, digital readouts for positioning both side bending rolls, and much more.

How it works

Standard Equipment

- Direct-Drive Design is featuring constant and powerful torque direct to the roll rotation.

- Sumitomo Cyclo® 6000 Gearless Speed Reducer.

- Spherical roller bearings on all rolls for longevity and constant use.

- Hydraulically powered bending rolls.

- Power tilting side bending rolls for cone rolling.

- Digital readouts for position of both side bending rolls.

- Hydraulically operated drop-end for quick removal of rolled product.

- Forward/Reverse rotation controls.

- Upper and lower pinch rolls driven.

- All rolls heat treated to 50 Rc.

- Manual tilt of the lower pinch roll.

- Adjusting tools, pinch gauge stock, technical manual.

Optional Equipment

-Cone bending attachment.

- Cable type Emergency stop device.

- Infinitely Variable Speed Control.

- Control Panel on Wheels.

- Top Supports.