Double Pinch Rolls

The Double Pinch Plate Bending Rolls, an universal machine for all plate bending jobs, especially for the job-shop fabricator. The design provides excellent prebending capabilities; it is easy to prebend both the leading and trailing edge. Fully hydraulic driven, hardened rolls, digital readouts and the adjustable various speed features make your rolling jobs easy and fast. The best choice of cone bending and thick material bending .

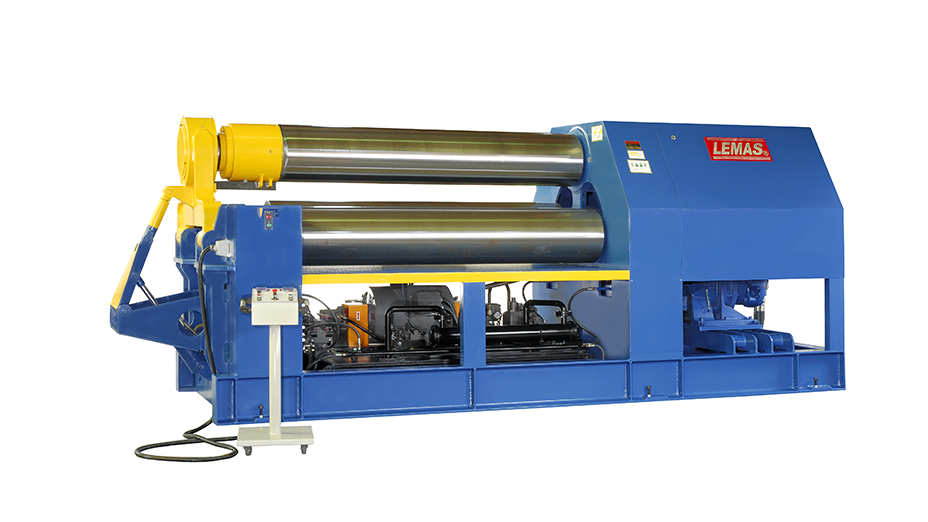

Hydraulic Double Pinch Plate Rolls

Three-Roll Type

The 3-Roll Plate Bending Rolls, an universal machine for all plate bending jobs, especially for the job-shop fabricator. The design provides excellent prebending capabilities; it is easy to prebend both the leading and trailing edge without removing, turn, and re-insert the plate. The bending result is the same as to rolled on a 4-roll machine. The two lower rolls hydraulic powered adjusted individually, and all 3 rolls rotate with adjustable rolling speeds, make you to control the rolling process more easily. The standard rolls are made of S45C carbon steel and heat treated to 50Rc. The drive system is using a high-quality hydraulic motor with a gearbox and chain drive all three rolls, allowing all rolls to provide 100% driving torque at all times. This drive system is the most effective system for drive torque and easy to maintain. Best for the cone bending and thick cylinder jobs.

Standard Equipment

- Full hydraulic drive and control system.

- PLC electric system.

- Hydraulically powered and operated roll rotation providing infinitely variable rolling speeds.

- Hydraulically powered and operated adjustment of the lower rolls with infinitely variable adjusting speeds.

- All rolls heat treated to 50 Rc.

- All adjustments are electronically controlled from the portable console by push buttons.

- Key-lock switch for On/Off for the power supply.

- Emergency stop button at the middle of the panel and the machine.

- Hydraulic drop end is designed with locking device for more safety.

- Digital readouts for showing the positions of the two adjustable bottom rolls.

- Both bottom rolls are individually and hydraulically tiltable for cone rolling by using push buttons.

- Paralleling adjustment after cone rolling by using push button.

- Cone rolling attachment.

- Instruction and parts manual and tool box.

Optional Equipment

- Motorized top Support device.

- Hydraulically operated Side Support device

Four-Roll Type

The 4-Roll Plate Bending Rolls provides the outstanding performance, reliability, and quality features to reach the requirements of high precision and high production rates. The hydraulic adjustment of the bending rolls and the lower pinch roll with separate convenient pinch pressure adjustment. In addition, both bending rolls are hydraulically tiltable for cone rolling, and the hydraulic drop end makes it simple to remove the completed cylinder from the rolls. Other standard features include adjustable rolling speed, cone rolling attachment, rolls heat treated to 50Rc, digital readouts for positioning both side bending rolls. Furthermore, it’s the best for doing mass production machine, and easy for new or unskilled operation to learn and operate the machine quickly.

Standard Equipment

- Full hydraulic drive and control system.

- PLC electric system.

- Hydraulically powered and operated roll rotation providing infinitely variable rolling speeds.

- Hydraulically powered and operated adjustment of the lower rolls with infinitely variable adjusting speeds.

- All rolls heat treated to 50 Rc

- All adjustments with are electronically controlled from the portable console by push buttons.

- Key-lock switch for On/Off for the power supply.

- Emergency stop button at the middle of the control panel.

- Hydraulic drop end is designed with locking device for more safety.

- Digital readouts for showing the positions of the adjustable lower rolls.

- All lower rolls are individually and hydraulically tiltable for cone rolling by using push buttons.

- Paralleling adjustment after cone rolling by using push button.

- Cone bending attachment.

- Instruction manual and tool box.

Optional Equipment

- Motorized top Support device.

- Hydraulically operated Side Support device.